Why do we need double sided printing

The end products are mainly for back lighting light box. The double sided light box is more vivid than single side.

Besides, the profit for double sided printing is much higher than single side. The are few affordable double sided printer in the market.

What the most important for double sided printing

The double sided printing is print Image on front, and print mirrored image at back side. When light on, even a slight misalignment can be easily caught. Thus the most important thing is alignment for both side.

The common sense is use mechanical precision to enable double sided printing. It can be done by print both side at same time or print front side first and then refeed again by printer itself to reduce manmade error. This makes the printer more complicate and expensive.

Besides mechanical presion, we also need the characteristics of affordable, effective. We develop a unique system to compensate any potential printer-made or manmade mistake.

How we print,

1. Print image on front side with two lines of crop-make(one crop mark per inch) at each side.

2. Replace the take up and feed system, reload media.

3. The cameras will trace crop mark each inch to let printer know where to print.

4. The software will do alignment every inch. Trace every inch's start and end point to calibrate where to print, thus the tolerance will within millimetre-size and never error will never accumulate.

5. At the same time, for media's width, it is seperate to 5 points. When media being fed, nedia tension will influence back side image's position, this function is a compensation.

Since our double sided working method is more than simply relied on mechanical presicion, print different image on block-out media, such as super hanging-scroll in shopping mall, is piece of cake.

Print Head: Two DX7

Type: Eco-Solvent

Ink Colors: CMYK 2*4Cartriages*350ml

Maximum Resolution: 720*1440dpi

Height of Printhead: Adjustable 2 to 5mm

Interface: USB 2.0

Printing width: 1.8m, 3.2m

4Pass Speed: 26sqm per hour per side for 77802(Support different pass on back side)

RIP Software: IPrint 3.0,Photoprint,Wasatch (SDK available for port of console)

Heater: Pre and Post heating to 80 celsius degree with PID control

Optional IR heater

Niche: Auto Real time tracking and correcting fine。

Double sided printed light box, block-out double side such as hanging scroll in shopping mall(unlimited size)

For A-Starjet 77802

Fumigation wooden box

Dimension(M): W x D x H 2.84 x 0.90 x 1.25 255kg

Packing 2.94 x 0.98 x 0.70 395kg

For A-Starjet 77802L

Fumigation wooden box

Dimension(M): W x D x H 4.30 x 0.90 x 1.25 430kg

Packing 4.45 x 1.13 x 1.45 610kg

Advantages:

A-Starjet is designed with the Idea of easy use, high flexibility and stable productivity. We made the first eco-solvent printer in China, and sold thousands control system for eco-solvent printer before we found our own factory.

We provide free and easy use Iprint Rip, special developed for A-Starjet. We keeps updating Iprint for better clients' satisfication. Now it is 16-bits version, provides better detail while printing image.

Single USB2.0 Port,

We update the data communication port from July, 2012. The faster the data transfer, the better the printer works. It also elimates USB error.

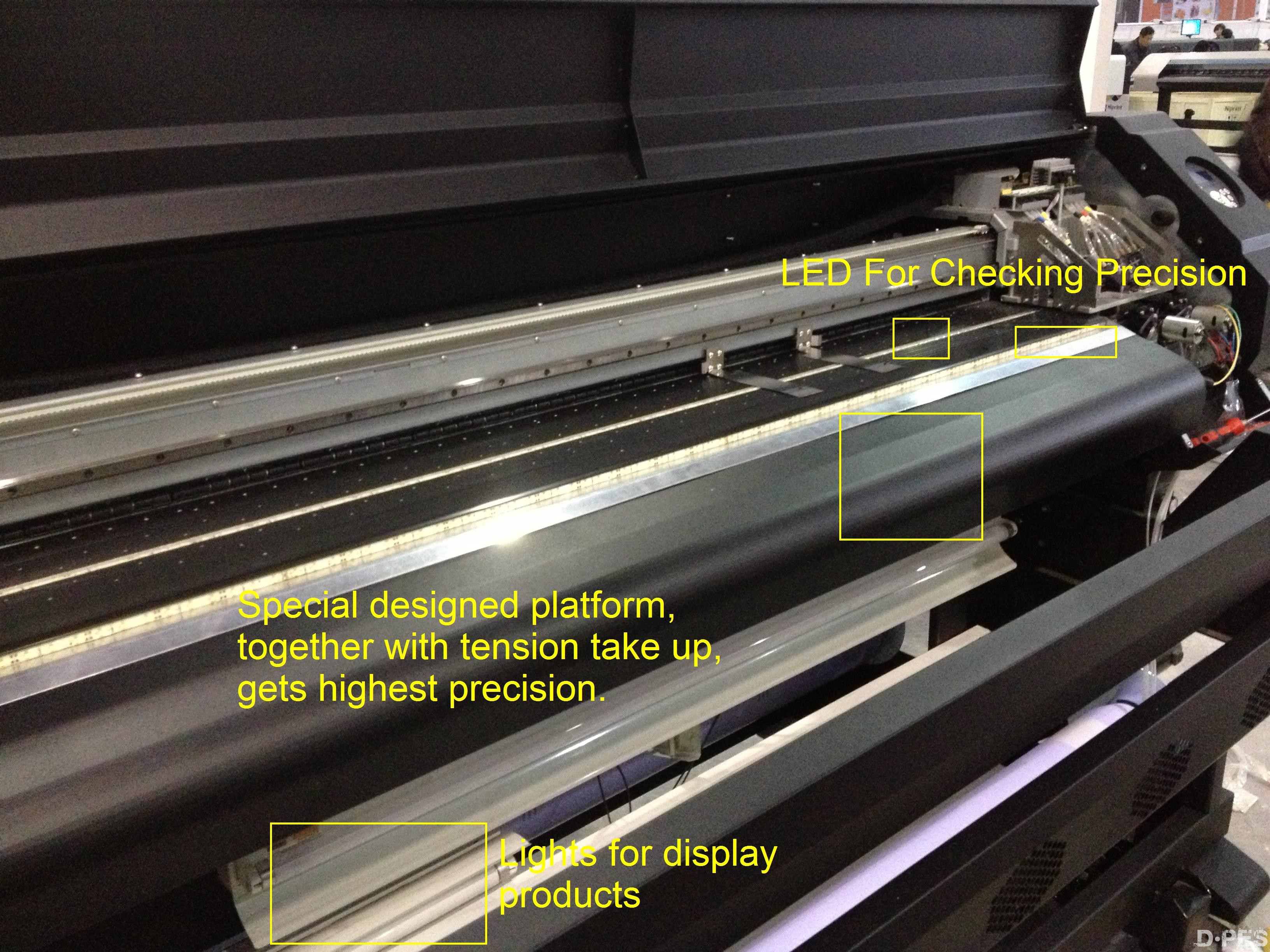

Special Designed Platform, Replaceable Tension Media Handle System,

While printing on back side, the ink on front side and media's tension will influence the precision. Considering the most important thing is double side precision. We redesigned the platform for tension media handle system. With the auto fine tune, which will be adjusted every per inch, the tolerance for media's length within millimetre-sized for each inch and tolerance won't accumulated.

The replaceable media handle system makes double sided printing more convenient.

DX7 Print Head,

DX7 printhead can take higher voltage than DX5, it makes it's print speed can be 15% faster than DX5. DX5 has different head(silve surface for water based, gold surface for eco solvent) while DX7 is one for all.

R&D Manufacturer,

All parts, softwares are made by ourown. We have enough experience on large format printing, to help clients to use printer, sell printer, do modification on software or printer to fit local market, these are acceptable.

After-sale Service:

Life-time free techinical support directly from manufacturer.

Official Service time: 8:30am to 5:30pm(GMT +8), Monday to Saturday by TEM8 qualified Engineer

Skype ID: "astarjetservice" Personal ID "zqw-na"

Mail: Postmaster@astarjet.com

Guarantee Term:

All parts directly contact with ink are not guaranteed except use A-Starjet's ink

5 months guaranteed for DC motor

15 months for all Boards

Counting from the day that printer leaves factory

Within Guarantee time, factory covers freight for sending parts